ePaper, evolution and experimentation: the ‘State of Display’

Engineering as a profession is an interesting juxtaposition of creativity and grounded thought. On the one hand, an engineer is responsible for driving product development with ideas and experiments, looking to defy expectations and innovate exciting new features. On the other, they are restricted by pragmatic concerns; what their consumers expect, what they can work with, and the expectations tied to their brand.

This is particularly important in the realm of personal electronics and devices. We spend so much time engaging with our screens, and yet the vast majority suffer from the same limitations. Why are we settling for an unimaginative field of ‘me-too’ products? Why is product design, and in particular the choice of display, so often approached through the same ‘glass’ ceiling?

Plastic Logic’s latest research, outlined in its ‘State of Display’ report, attempts to address these questions based on a survey of 115 professional engineers involved in the outline specification or physical design of electronic products that feature integrated displays.

The findings suggest that engineers are struggling to deviate from the materials that consumers and industry professionals are used to incorporating into their products. If engineers were empowered to experiment and push beyond their comfort zone, they would have more success in eliminating the frustrations of conventional display technology.

Are innovative engineers engineering innovation?

The importance of innovation in engineering is recognised both as an obligation and a priority. 83 percent of the engineers surveyed consider innovating new product features as important, and 44 percent are actively required to innovate new product as a critical part of their projects. It’s obvious that innovation is crucial in providing something unique to consumers.

Next: Creative license

Most engineers also hold healthy levels of creative license. 66 percent consider the choice of display to have a major impact on the final product, and 36 percent are even given free rein to choose the display solution to incorporate in their final designs. The display is considered crucial, and engineers have the power to experiment with the best materials for it.

Unfortunately, this isn’t translating into innovative product design; the vast majority of engineers (80 percent) are failing to conduct rigorous assessments of display technology in their design projects. Most are also failing to review their display technology regularly, with almost half conducting a review or refresh only every two years.

This overall hesitancy towards due diligence and experimentation suggests that huge opportunities to create differentiation and competitive advantage are routinely missed. With a window of potentially years between each review, and only 20 percent of engineers making serious effort to experiment with alternatives technologies when this review identifies issues, it’s no surprise that consumers are running into the same old frustrations with the same old products.

If products employ the same display materials within their designs, they are going to suffer from the same drawbacks and limitations. The engineers surveyed demonstrated a clear hegemony in display materials, with 62 percent using either LCD Graphical (35 percent) or OLED (27 percent) in designs from the past twelve months alone. Consequently, users are left trying to differentiate between competing products, without being able to select one that addresses the weaknesses of the other.

What makes ePaper different?

This uniformity doesn’t only cause trouble for the consumers. The popularity of glass displays in product design means that engineers are forced to designing their devices in ways that mitigate its weaknesses.

Glass is cheap, easy to mass-produce, familiar to consumers, and provides great visual fidelity. However, these strengths come at a cost in terms of durability, power consumption, and reflectivity. OLED and LCD Graphical displays cannot be read under direct sunlight, are notoriously power-hungry, cannot bend, and have negligible resistance to impact damage.

When engineers were asked what qualities of a display they valued highest, they specified these weaknesses. Ruggedness (37 percent), outdoor readability (31 percent) and power consumption (30 percent) were of the highest priority because they are the attributes that engineers working with glass aim to achieve.

Next: Growing popularity

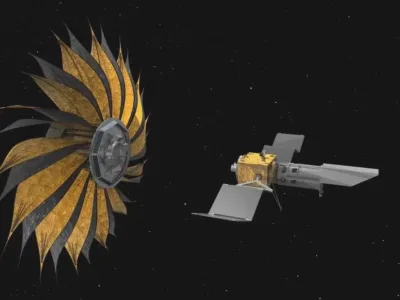

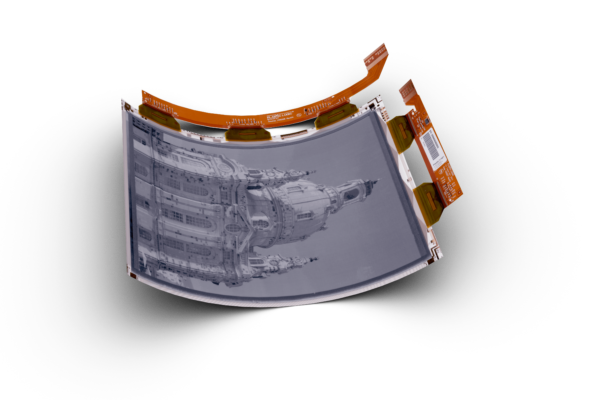

The growing popularity of ePaper is partially due to its strengths in these areas. ePaper is well-suited to deployment under direct sunlight thanks to its non-reflective properties. It can also take advantage of solar power sources, but with power only needed to change the image on the screen rather than to maintain it, ePaper offers exceptionally low-power consumption regardless. There are also ingenious cases where ePaper is being developed into flexible displays that demonstrate greater durability, resistant to snapping, blunt force, or scratches.

ePaper’s particularly ability to combat specific issues in glass and LCD display design is encouraging engineers to utilise the material, with 60 percent stating that they were likely or very likely to employ ePaper in the future. However, current usage remains low: only 5 percent of those surveyed are using ePaper in their current designs, and two thirds have never used the technology before.

To explain why few engineers are using ePaper now, despite a clear desire to use it in the future, we have to go beyond the attitudes of the engineer and analyse the supply chain that they interact with.

Supply and Demand

As we’ve seen so far, engineers are generally reticent to introduce experimental materials into their display designs. A lack of familiarity and understanding of the benefits, perceived cost, and the challenges of justifying new technology were all common reasons for engineers to avoid a switch to more experimental materials, even though they may be more suitable to address the challenges that they face.

However, there is a contingent of engineers who are still motivated to experiment, and who recognise the suitability of ePaper to combat their issues. Experimental materials require successful use cases to reach the mainstream, and these are driven in the early stages by a minority of visionaries who see value in the technology.

To facilitate these cases, engineers are reliant upon their supply chain. They need access to test kits, samples of differing sizes, and other utilities that will form the building blocks of their experiments as they familiarise themselves with the material and integrate it into their technology.

Next: Let down

Unfortunately, the ‘State of Display’ report indicates that engineers are being let down by the display supply chain rather than being empowered by it. Materials are hard to source, there is limited guidance for those new to the technology, and vendors will naturally lean towards high-volume orders to maximise their profits and to ensure that their stock is moved in bulk.

About 49 percent of engineers in our survey struggle with prototyping due to the availability of samples, and 55 percent find it challenging to get development kits operating quickly when trying to integrate displays into their product. The display supply chain is thereby creating a barrier to the very thing it should be encouraging!

To counteract this challenge, it’s important that engineers work with a strong and supportive partner. With the help of a trusted supply chain partner, the barriers affiliated with prototyping due to display sample availability should also diminish and engineers will be better-placed to evolve a great concept into a disruptive, market-leading product or service in this incredibly competitive marketplace.

So where can we see successful experiments with ePaper?

Despite the logistical difficulties of experimental materials, their unusual qualities still lead to incredibly creative use cases. If supply chains can help create space for innovation, encouraging and enabling engineers to innovate, we will continue to see innovative ideas come to light.

Once again, ePaper is an extremely interesting example. In terms of conventional usage, it has begun to find integration both into personal devices over the past decade. The advent of the eReader, allowing users to carry a digital library with them without the eyestrain caused by LCD or OLED displays, is the most well-known example and has given rise to a host of brands competing to develop the best device.

Beyond this, ePaper has also found great success as a public utility, particularly when deployed in urban areas. Transport for London has trialled ePaper bus timetables in 2016 with great success, with similar schemes taking place from Germany to Japan. As a low-power display that is resistant to vandalism or accidental damage, ePaper is extremely well-suited for applications in busy cities.

Pushing the envelope even further is the incorporation of ePaper into the popular sphere in fashion or art. Brands as big as Google and Levi’s are collaborating to produce smart clothing that can synchronise with the personal devices that people own, and researchers at the University of Buffalo are using a type of ePaper for Kirigami – a form of origami – which allows the construction of malleable electronic circuits within the artwork itself.

These examples are all indicative of the immense versatility that ePaper has to offer. When engineers are given the opportunity to push beyond their comfort zone, they are capable of utilising ePaper in a huge variety of ways, which can only help consumers get closer to the personal experience that they seek.

Ultimately, the ‘State of Display’ report suggests that engineers need to commit to creativity and unconventionality over practicality and conformity if they are to discover the most effective ways to address the frustrations of both themselves and their consumers. To do this, they will need to cooperate with their suppliers to facilitate a creative environment, collaborating in efforts to drive innovation and experimentation.

Tim Burne has been CEO of Plastic Logic since January 2015 and was chief strategy officer of the company prior to that. Plastic Logic’s survey was undertaken during March and April 2018. It was completed by 115 professional electronics engineers specifically involved in the outline specification or physical design of electronic products featuring integrated displays.

Related links and articles:

News articles:

Plastic Logic shows 500ppi display

E Ink renews agreement with Plastic Logic

Nanoscale kirigamis manipulate light

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News